Streamline your manufacturing operations with our comprehensive factory management system. Track production, manage inventory, monitor employees, and optimize your entire workflow.

Comprehensive tools designed to optimize your manufacturing operations and streamline your factory management processes.

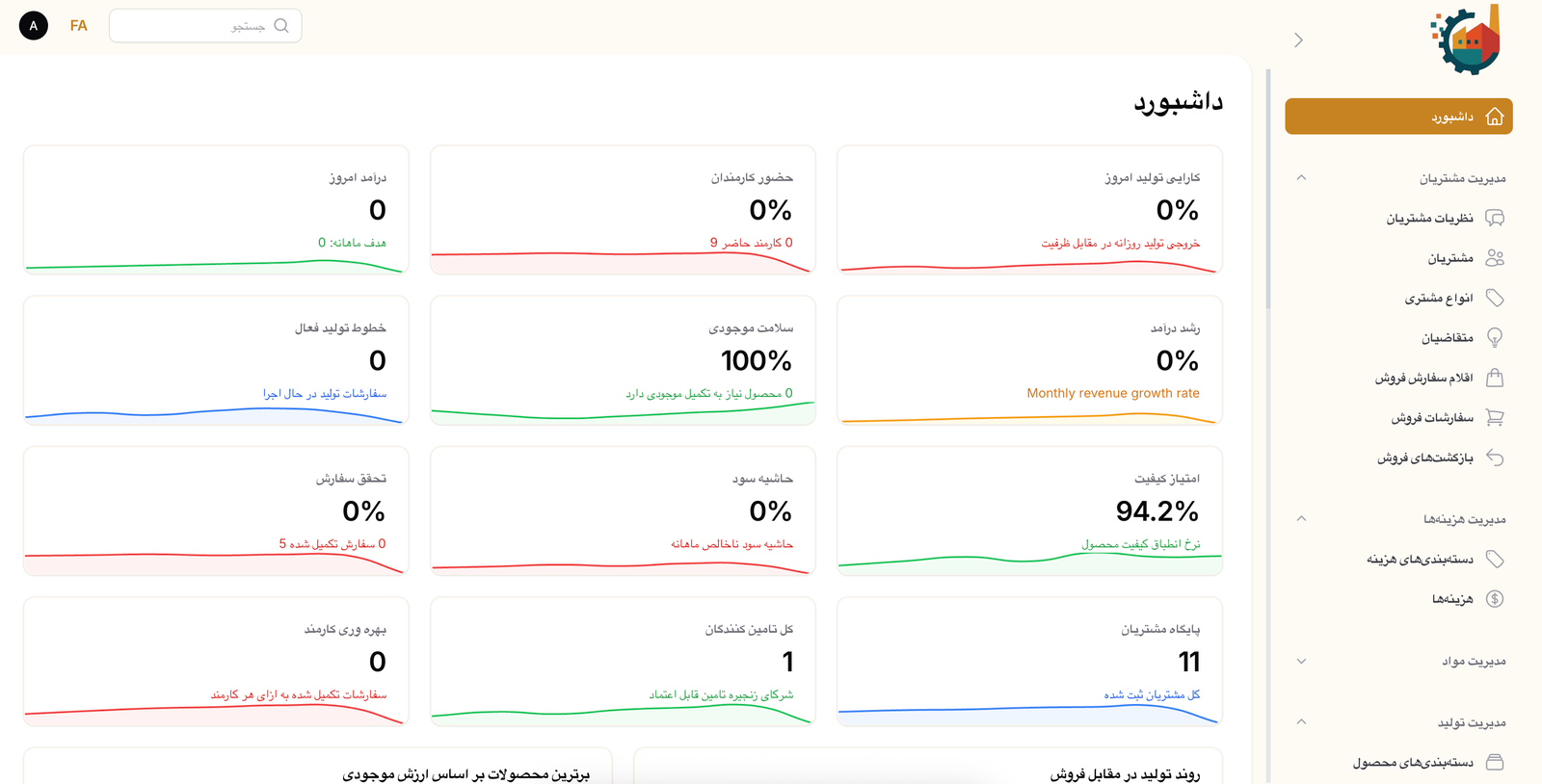

Real-time tracking of production lines, output rates, and quality metrics to ensure optimal manufacturing performance.

Complete control over raw materials, finished goods, and supplies with automated reorder points and real-time stock tracking.

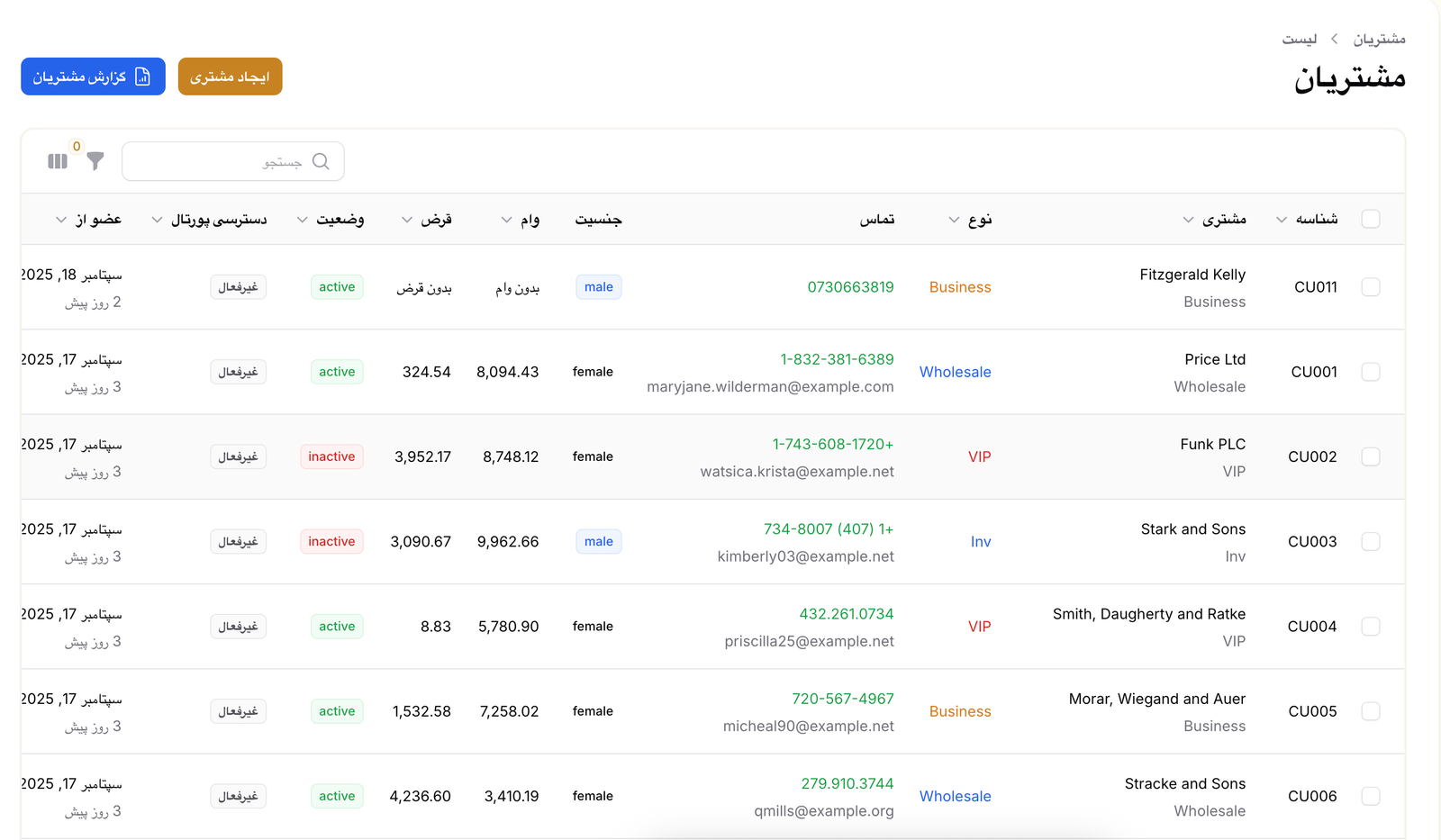

Track employee attendance, manage shifts, monitor performance, and handle payroll with comprehensive workforce management tools.

Implement quality assurance protocols, track defects, manage inspections, and ensure consistent product quality throughout your manufacturing process.

Our comprehensive factory management system provides real-time visibility

into your manufacturing operations, helping you optimize production efficiency,

reduce waste, and improve quality control.

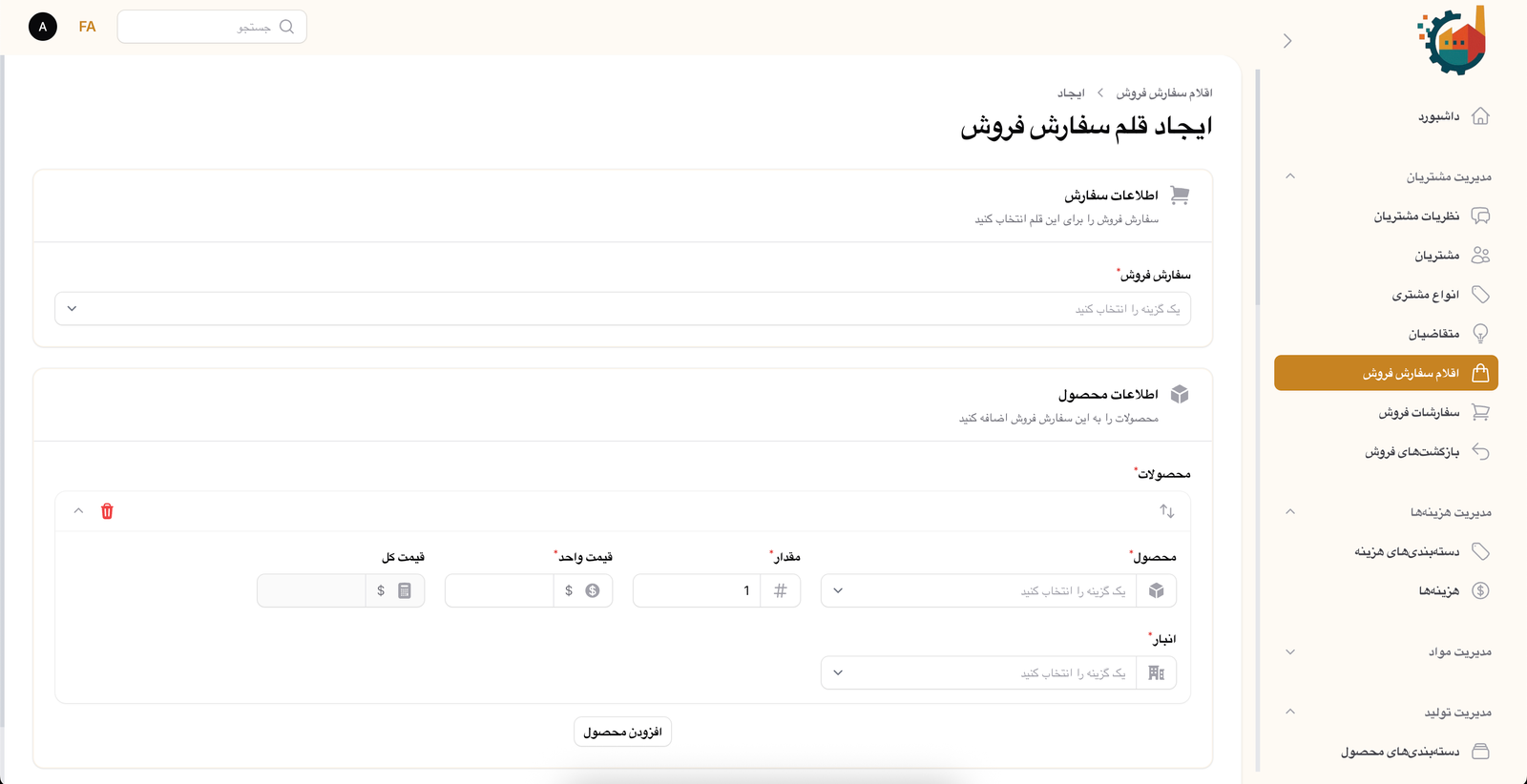

From inventory management to employee tracking, production monitoring to

quality assurance, our system integrates all aspects of your factory operations

into one powerful platform.

There are many variations of passages of Lorem Ipsum but the majority have suffered in some form.

See the DemoFind answers to common questions about our factory management system and how it can help streamline your manufacturing operations.

The system includes production monitoring, inventory management, employee tracking, quality control, real-time reporting, and automated alerts. You also get mobile access, data backup, and integration with existing systems. All features are designed to work together seamlessly for maximum efficiency.

The system includes production monitoring, inventory management, employee tracking, quality control, real-time reporting, and automated alerts. You also get mobile access, data backup, and integration with existing systems. All features are designed to work together seamlessly for maximum efficiency.

The system includes production monitoring, inventory management, employee tracking, quality control, real-time reporting, and automated alerts. You also get mobile access, data backup, and integration with existing systems. All features are designed to work together seamlessly for maximum efficiency.

Implementation typically takes 3-8 days depending on your factory size and complexity. Our team will work with you to set up the system, migrate your existing data, train your staff, and ensure everything is running smoothly before going live.